Funding body: EPSRC-GCRF (Engineering and Physical Science Research Council – Global Challenges Research Fund)

Project reference: EP/P511171/1

Project duration: 3 years

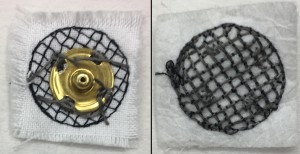

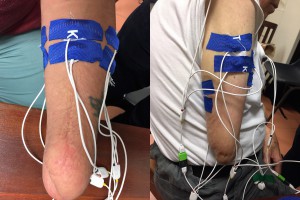

This project consists in exploring the feasibility of integrating a low-cost sensing system based on textile technology to 3D-printed prosthetics to propose a limb replacement solution for amputees in the developing world. In the project, textile electrodes developed at King’s College London [1] are used with an electromyography (EMG) signal acquisition system associated with the Touch Hand (an affordable robotic prosthesis) [2] developed at the University of KwaZulu-Natal. Current high-end prosthetic hands in the developed world have shown their potential to have performance similar to the human hand. However, the best solutions are often too expensive for patients in developing countries [3]. The Touch Hand has been developed to propose a solution suitable for the developing world market with a modular design. As an interface between the human body and the device, electrodes play a major role in myoelectric prostheses. Single-use gel electrodes are the state-of-the-art interface as it is the best solution for high quality bio-signal recording, but they could present an issue in the developing world due to their cost in regular replacement, and the expertise needed in using them. The embroidered textile electrodes are here presented as an affordable alternative, and we are testing their use for gesture recognition in hand myographic prosthetics for control of different grasps. They are sewn with a programmable sewing machine using stainless-steel conductive thread and they present many advantages: they are flexible, reusable, washable, and easy to produce. The aim of complementing low-cost prosthetics with textile electrodes is to propose a solution that can be built in the developing countries, requiring a low amount of raw materials and no technical knowledge to assemble. It will also encourage the production in the developing country and the creation of employment in the textile and technological industries.

The performance of the embroidered textile electrodes in hand gesture recognition will be studied for the first time. EMG data from amputees in South Africa were collected with the textile electrodes for this study. Then, hand-sewn textile electrodes will be designed and compared to machine-sewn textile electrodes to study the possibility of using them for EMG signal recording.

Research themes:

- Smart textile

- Low-Cost Prosthetics

- Machine-Learning

- Human-Robot Interaction

- Biosignal Measurements

References

[1] A. Shafti, R. B. R. Manero, A. M. Borg, K. Althoefer, and M. J.Howard, “Designing embroidered electrodes for wearable surface electromyography,” Proceedings - IEEE International Conference on Robotics and Automation, vol. 2016-June, pp. 172–177, 2016.

[2] G. Jones and R. Stopforth, “Mechanical design and development of the Touch Hand II prosthetic hand,” R&D Journal of the South African Institution of Mechanical Engineering, vol. 32, pp. 23–34, August 2016.

[3] D. Van Der Riet, R. Stopforth, G. Bright, and O. Diegel, “An overview and comparison of upper limb prosthetics,” IEEE AFRICON Conference, 2013.

[4] Mangezi, A, Rosendo, A, Howard, MJW & Stopforth, R 2017, Embridered Archimedean spiral electrodes for contactless prosthetic control. In The 15th IEEE Conference of Rehabilitation Robotics (ICORR 2017). IEEE, London.